3D Product Visualization & Design

At Levi’s, I help shape how product form, material, and construction come together across the softgoods line. My work lives in that space between concept and reality, where ideas are tested, refined, and made tangible through pattern-accurate 3D builds.

Each piece starts as an exploration of proportion, silhouette, and material behavior. I use CLO3D to study how structure, tension, and seam placement define the final form, tuning details until the product feels resolved both visually and functionally.

These 3D prototypes serve as design validation tools, guiding conversations around form language, ergonomics, and manufacturing feasibility. It’s a process built on iteration, intention, and the pursuit of that perfect balance between aesthetic clarity and real-world performance.

Extensive Portfolio of 3D Models

This collection highlights the range of 3D design work I’ve created for Levi’s, spanning packs, totes, headwear, and belts. Each piece represents an exploration of form, proportion, and material, built to reflect the brand’s evolving identity while staying rooted in real-world manufacturability.

Across hundreds of product models, I’ve refined silhouettes, tuned construction, and developed lifelike visualizations that support both design validation and storytelling. My focus is on balancing creativity with technical precision, translating the tactile qualities of denim, leather, and hardware into digital materials that feel authentic to Levi’s heritage.

This body of work captures how I approach softgoods design as a whole: merging digital craft, material understanding, and design intent into a unified visual language that connects concept to product.

Design Development, Patterning & Visualization Process

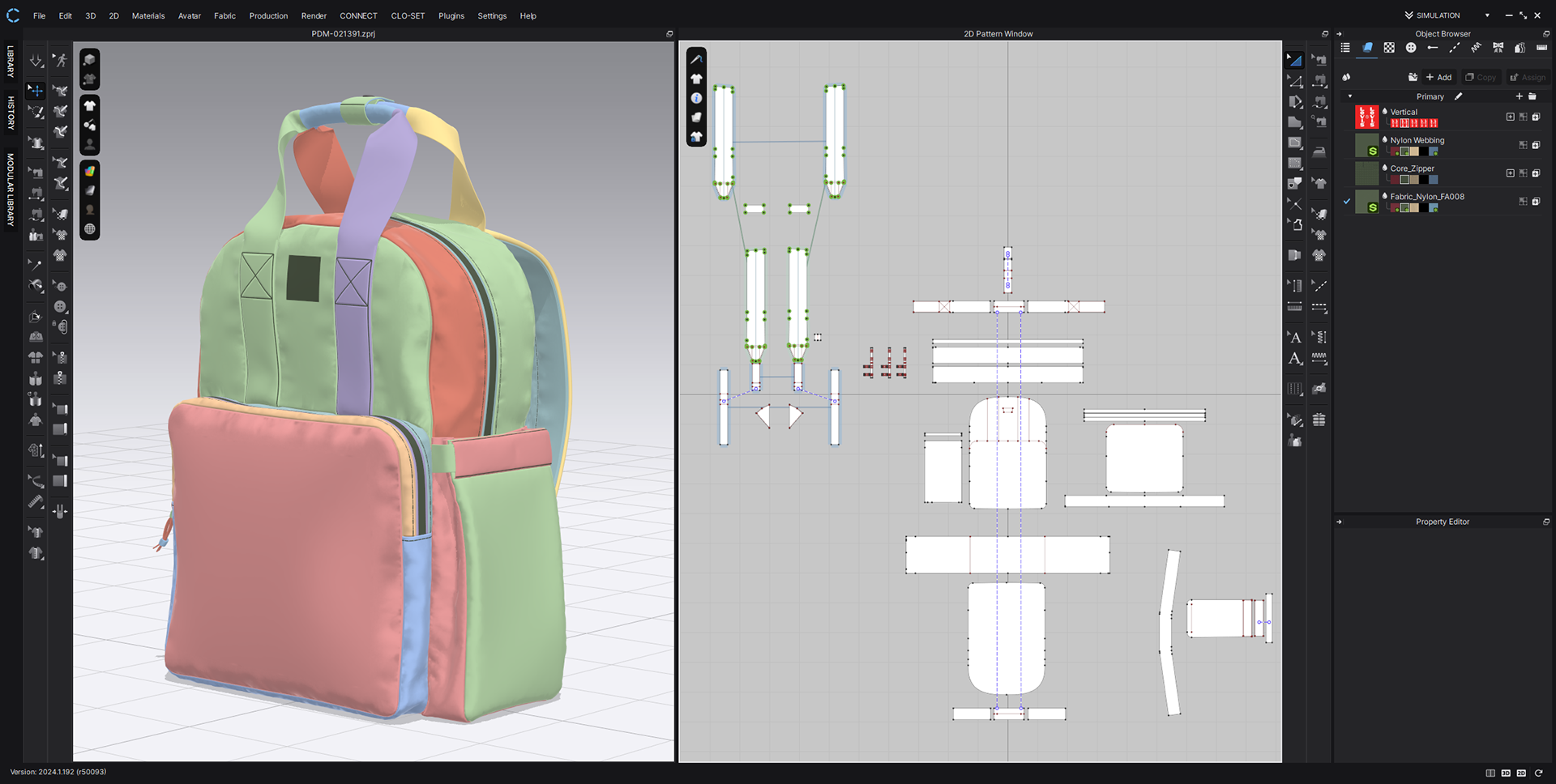

Patterning & 3D Modeling

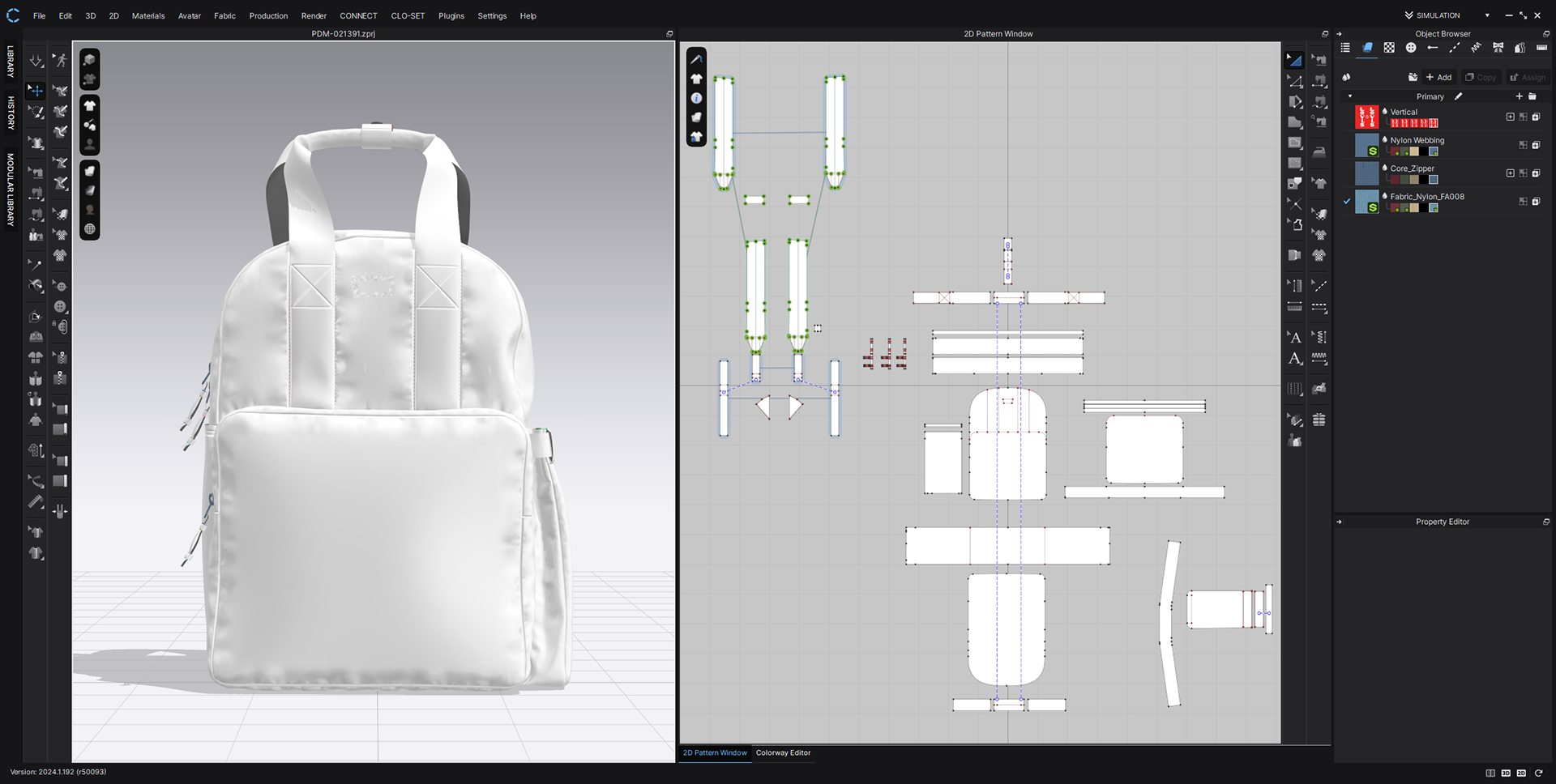

Every project begins with a focus on proportion, structure, and how the product moves. I build pattern-accurate 3D models that define fit and construction, allowing form and functionality to evolve together.

Material & Texture Mapping

Digital materials are tuned to capture the tactile essence of the real product, highlighting surface tension, grain, and sheen so the visuals communicate both design intent and material truth.

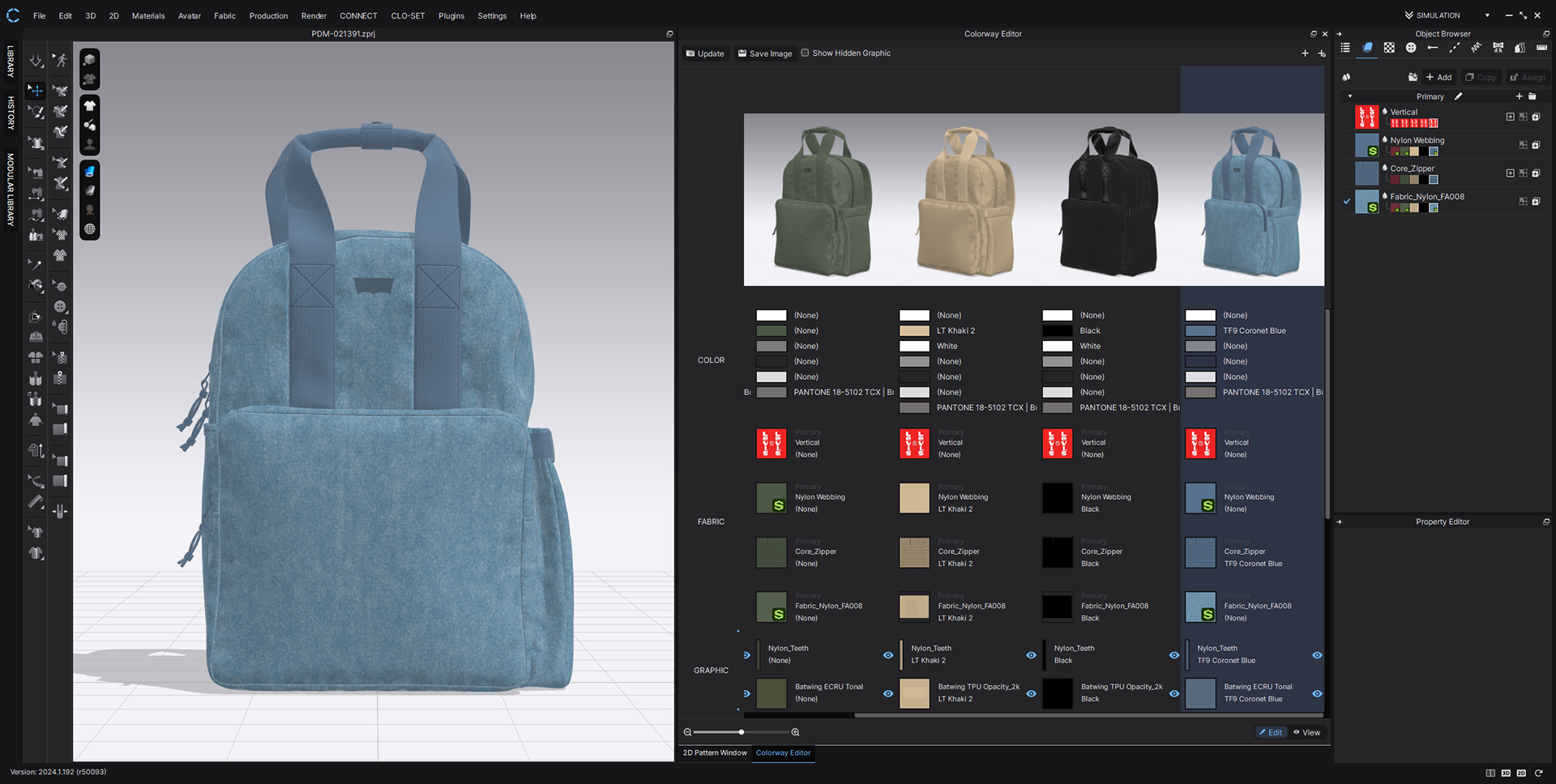

Colorway Exploration

Multiple palettes are tested to explore mood, seasonality, and brand expression, pushing beyond simple color swaps to define the product’s visual voice.

Logo & Branding Studies

Using RGB separation techniques, I develop and visualize alternate logo placements and finishes. Each channel represents a unique concept, helping teams evaluate brand integration in context.